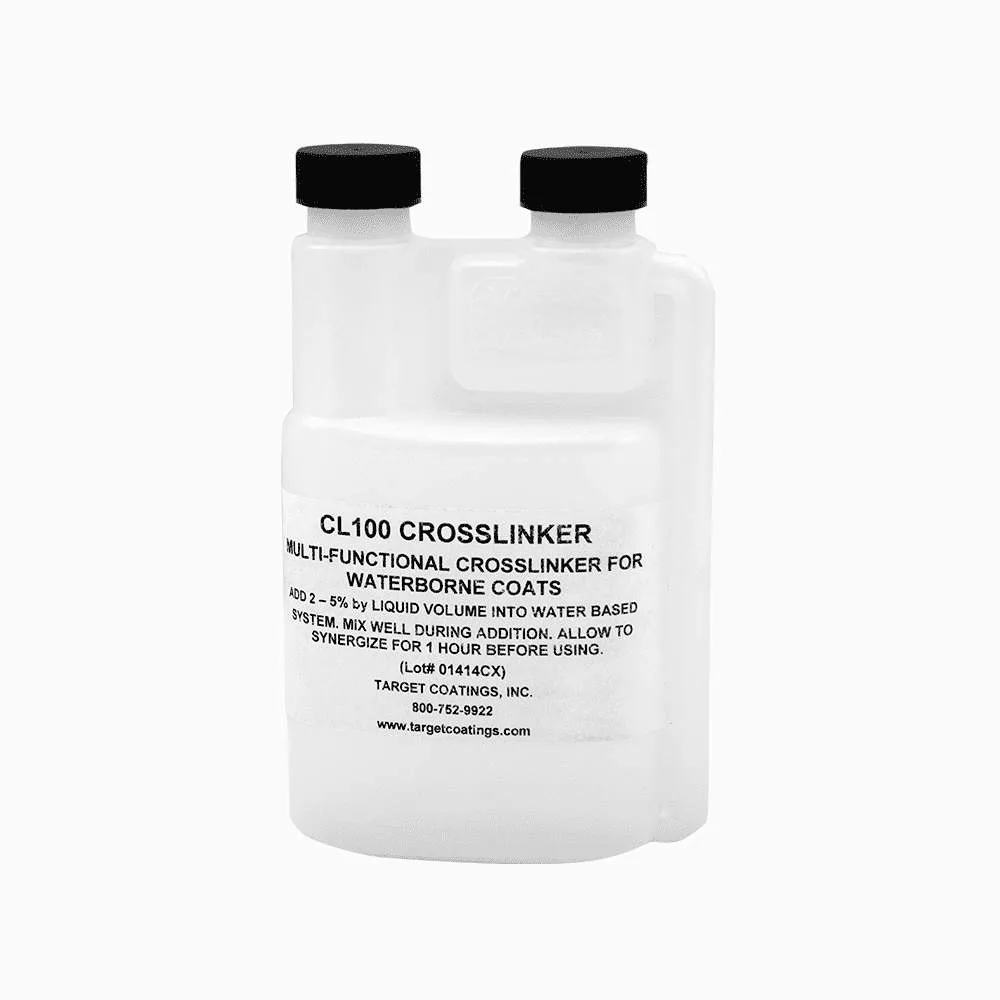

CL100: Give your Finish a Boost to the Next Level

100% Water Soluble for our 100% Water Based Coatings and Finishes

CL100 CrossLinker is a water soluble chemical additive used to elevate the durability, appearance, water and chemical resistance of waterborne coatings by coupling the resin molecules of the film forming finish into tighter and stronger bonds when fully cured. Our crosslinker is engineered to give a performance boost to the physical characteristics of the finish it is being blended into. CL100 increases the coating’s resistance to alcohols and high pH cleaners allowing it to withstand a longer exposure time to corrosive chemicals. Unlike other catalysts and crosslinkers on the market that can contain isocyanates and aziridine which can be very harmful to the spray applicator’s health, our crosslinker is an ester diol blend that is far less toxic and much safer during application. CL100 is non-flammable and does not increase the VOC content of our coatings, maintaining each coating’s already low VOC content and your health and safety during application.

In most wood finishing applications it is unnecessary to add CL100 as an additive to our coatings. We recommend the use of CL100 for specific finishing scenarios that call for extra durability and alcohol, water, or detergent resistance. Examples of these scenarios are commercial applications where the coating will receive a lot of chemical abuse from patrons and cleaning staff or residential applications where heavy and frequent use and abuse of a cabinet or piece of furniture necessitates the need for a more durable and long lasting finish. Examples of residential applications where CL100 could be used are a dining room tabletop or coffee tabletop that is frequently used or a bathroom vanity that sees daily use and frequent cleaning.

A crosslinker that has a long pot life and won’t ruin your unused coating or spray gun

Unlike acid catalysts, which have a very short pot life, our water based CL100 is reactive to oxygen only when the coating is allowed to form a film and air dry. This greatly increases the pot life of finishes fortified with CL100 CrossLinker which will remain functional for upwards of 100+ hours when stored in a sealed container and will not harden in your spray gun, creating a nightmare scenario for cleanup. These features eliminate the expensive loss and waste of unused material.

What if you’re not able to use all your CL100 fortified finish in 100 hours? No problem, just add another 1-2% by liquid volume to re-synergize the components and continue to use your mixture.