Superior finish on complex woods (i.e. African Padauk)

For more than thirty years I’ve chased the ever-receding horizon of perfection, marrying technology to the warmth of wood so each piece delivers both poetry and everyday utility. That pursuit has taken me through the full catalog of traditional oil varnishes, lacquers, and hybrid potions. Too often they have asked me to compromise: toxic chemicals, harsh solvents, fire-risk rags, fussy pot lives, unpredictable color shift, lingering odors, and sticker shock at the cash register. I wanted the depth and durability oils confer, minus the toxins and drama.

Enter Target Coatings. I first rolled the dice on their Emtech 1000 Universal Sanding Sealer. Laid down through an HVLP gun (DeVilbiss DV1 1.3 tip @ 20-25 PSI) it atomized like a dream, settling into the grain of black walnut and African padauk with a clarity that seemed to switch the “depth” **** to full. Once burnished back with 400-grit, the surface felt glass-flat yet alive with exceptional depth and character.

Top-coating with Emtech 9300 Polycarbonate Urethane Matte sealed the deal, literally and figuratively. A year later my daughter’s art-and-snack table still shrugs off watercolor, glue, and the occasional spaghetti night. There’s zero yellowing, no plastic sheen, and, best of all, cleanup is a quick rinse instead of a hazardous lacquer-thinner bath. The finish simply disappears and lets the wood sing.

When my wife commissioned a six-foot armoire that would dominate our sunroom, I reached for the new EMCAT+ Si427 Sealer & Isolator plus EMCAT+ 2K Conversion Varnish system. It sprayed buttery smooth, leveled out quickly, and stacked for re-coat without any trouble. Padauk’s notoriously fugitive crimson remains vivid and brilliant, not the dull greyish red other finishes encourage, while the film locks down at an exceptionally durable hardness.

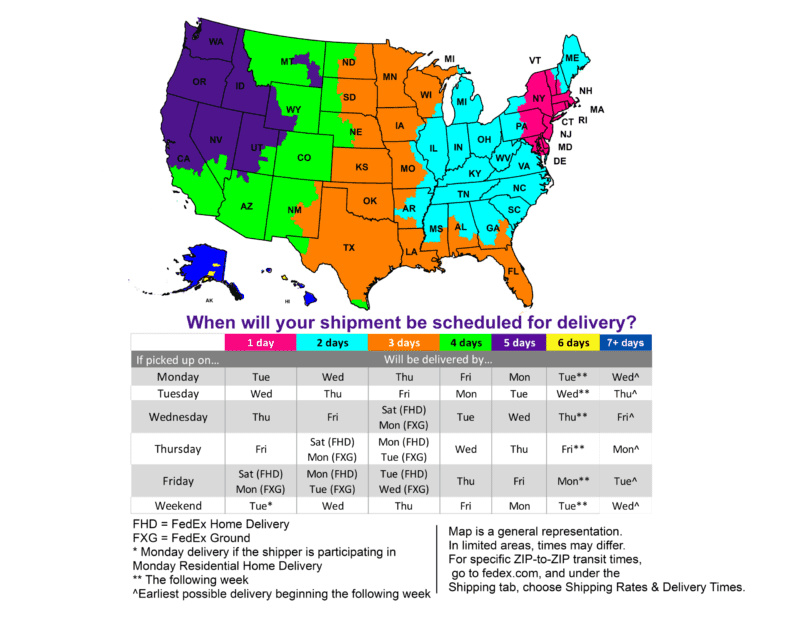

Across species such as African padauk, black walnut, and hard maple, the Target Coatings lineup has proven color-true, block-resistant, and blissfully forgiving of shop humidity swings. No blush, no witness lines, and no surprise adhesion failures when I edge-sand through a coat. The math is compelling too: no oily rags spontaneously combusting, easy cleanup with water, and affordability with super fast shipping.

I began this experiment hoping merely to reduce toxins; I ended up upgrading both aesthetic and performance. Target Coatings has earned a permanent shelf in my finish cabinet (literally the entire shelf now), and, judging by my clients’ double-takes, a permanent place in their living rooms as well.

Thanks Jeff. I use a lot of gel stains for refinishing or trying to get a specific effect. I’ve had problems before with my clear coats turning purple over dark stains. I usually use either General Finishes or Old Masters. I’ve been letting the stains dry at least 24 hours and most of the time 36 or greater. Wipe with 50/50 then a very light coat of Ultraseal and have had pretty good luck with going over these types of stains. If I don’t wait for that long, I find I’m picking up stain and moving it around and that’s not a very nice look. Thanks for expanding on the process.

What about underneath an oil based stain as a pre stain conditioner? Can the EM1000 be used as a pre stain conditioner on maple wood to prevent blotching, with a minwax oil based stain next, and then finishing with EM6000? Or maybe Em1000, oil based stain, EM1000 tack coat, Em6000 final coats?

MJ – It is best not to use EM1000 as a prestain sealer underneath an oil/solvent-based stain without creating a test panel to confirm that the two different products are compatible.

If you do find that the two products work in unison then proceed.

-JW-

I am preparing to finish a steamers trunk with an oil based stain followed by a light coat of water based poly followed by a water based glaze effects finish. Finally with two coats of water based poly. Do I need to wipe down the stained surface with the 50/50 denatured alcohol before applying the poly? Are there any other nuances I should be aware of?

Jerry,

Yes, we always recommend the wiping down of oil based products after they have thoroughly dried with a solution of 1:1 water and denatured or isopropyl alcohol. This ensures the surface is clean from any residual oils or wax that might be on the surface after the product has dried. We also recommend that your first coat over the stain be very thin to help with bonding to oil based product.

-SK

I am a painting contractor. My work with fence stain is limited. My customer has a nice, eight foot fence and appears to have a rich oil stain on it. She wants to have a solid or semi solid stain on it. Those products seem to be waterborne stains, which is what I have found at Sherwin Williams. My question is; can I put this water based stain over that transparent oil stain? If so, what prep work is involved?

Hi David,

Thanks for commenting on this post. We do not recommend our stains for this type of application. These stains are designed for interior projects or light duty exterior projects and they need to be topcoated with the appropriate clear coat. They are not a finishing exterior deck or siding stain. I recommend you look for an alternate product. Thank you for your interest in our coatings.

-Seth Kline