Updated December 2025

A Personal Note from Jeff Weiss

Back in October 2024, you may have read about Target Coatings launching a new brand called EMCAT+®.

At the time, maybe your reaction was, “Hey, this stuff sounds cool, but what the heck are they talking about?”

Well, not wanting to be accused of overselling my years of work in the lab by creating a massive new brand announcement, I took a soft-sell approach.

(It’s not the first time — I’ve repeatedly been told by venture capital guys that I am a professional soft seller of some of the most unique waterborne wood coatings technology in the past 40 years.)

Hey, I love a compliment, so whereas the full EMCAT+® line had been available only to a small group of professional wood finishers, I am now breaking free of my self-restraint and swinging for the proverbial fences by offering both products — Si427 Sealer / Isolator and EC2A Topcoat Kit — to all who want to use them.

So, why did I wait nine months to fully open EMCAT+® System to everyone, especially after nearly three years of work in the lab to deliver pro-level performance?

Well, we live in a funny world these days — one in which successes are mere social media clicks away, and disasters live on forever.

So, not wanting to be one of the “pop-up companies” that flame out before their flash is even seen, I wanted to ensure my EMCAT+® system is everything I found it to be behind my laboratory doors.

Call me slightly cynical, but the wood coatings industry is tripping over “me too” brands, and they are fighting over every last one of the finishing booth heroes that pop up on the social media radar.

Let’s face it, folks, it’s ugly out there. What was once a technology-driven industry has now become 100% commodity-driven. It’s a dirty game of “me too,” formula hustlers, and markets flooded by offshore brands.

So what’s a well-established boutique formulator like Target Coatings supposed to do?

My answer was to make something completely different.

Thus, with no more fanfare than I allow myself at any other time in my long history of top-shelf formulating, I bring you EMCAT+®.

Part 1: The EMCAT+® Acrylic Polymer Coating System

Since founding Target Coatings nearly 40 years ago, my mission has been to innovate — to create smarter, safer, and more versatile solutions that exceed the performance expectations of professional wood finishers.

Well, EMCAT+ is our most advanced waterborne wood finish yet.

What Makes EMCAT+ ® Different?

Many waterborne coatings struggle with dense woods and oily exotics — and they often fail to deliver the depth and warmth of solvent-based finishes. EMCAT+® changes that…without exposing you to toxic catalysts.

Here’s how it works:

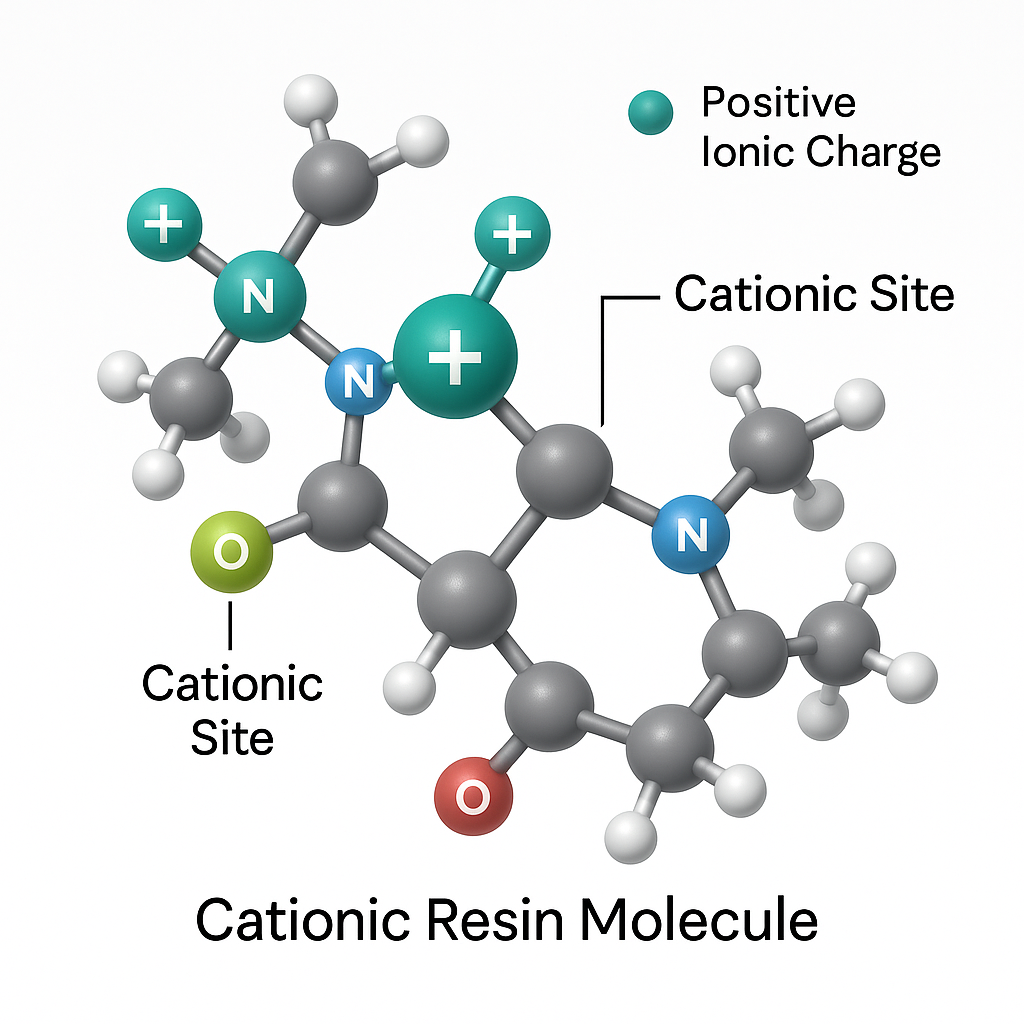

Cationic Resin Technology: EMCAT+® is built on a foundation of ultra-clear acrylic polymers which carry a positive molecular charge, enabling them to bond stronger, harder, and faster to challenging substrates, including oily woods, synthetics, and metals like brass and stainless steel.

True Color Reveal: EMCAT+® finishes mimic the visual richness of traditional solvent-based coatings, enhancing natural wood tones without the hazards of flammable solvents.

Cross-Compatibility: The system bonds seamlessly to previously finished surfaces, including those coated with anionic, conventional finishes—making it an excellent choice for refinishing or blending jobs.

Personal, Environmental and Workplace Safety: The EMCAT+® system does not use highly toxic isocyanate or aziridine catalysts typically found in 2K coatings. Instead, EMCAT+® uses a safer, proprietary, acid-functional organosilane compound catalyst, which does not have the long term exposure health risks that are common with isocyanate (blocked, or otherwise) and polyfunctional aziridine.

What Products Make Up the EMCAT+ ® System?

EMCAT+® is available in two key components:

EMCAT+® EC2A 2K Acrylic Topcoat: This two-component (2K) topcoat is the most chemical-resistant finish Target Coatings has ever made.

Designed as a replacement for 2K urethanes, EMCAT+® EC2A is NOT a urethane — it is an acrylic compound — and our proprietary EMCAT+® EC2B catalyst is a safe, non-isocyanate, and non-aziridine alternative designed to provide a complete chemical bond without the health risks associated with conventional 2K systems.

EMCAT+® Si427 Sealer & Isolator: This single-component (1K) sealer that acts as a “barrier coat” for challenging substrates such as acidic, oily or chemically treated wood.

EMCAT+® Si427 Sealer & Isolator can be used underneath the EC2A topcoat or any Emtech® brand waterborne wood finish to provides exceptional substrate isolation, clarity, and adhesion on both porous and non-porous surfaces.

I hope that gives you a good overview of what EMCAT+® is all about.

In part 2, I’ll show you how EMCAT+® performed in the ASTM D1308-20 chemical resistance test.

If you’re not familiar, this is the standardized test that evaluates how well a given coating stands up to a variety of common/household substances that your project might encounter (such as coffee, bleach, alcohol, oil, etc).

Here are those results:

Part 2: EMCAT+ Chemical Resistance Testing

A major milestone in the development of the EMCAT+ system was verifying its “real-world performance.”

So, I conducted extensive testing using ASTM Standard D1308-20, which evaluates the resistance of coatings to household and light-commercial chemicals, noting changes like discoloration, loss of gloss, blistering, softening, swelling, and loss of adhesion.

TEST SETUP OVERVIEW:

Date Initiated: October 4, 2024

Substrate: Walnut veneer bonded to MDF core

Sealer: EMCAT+ Si427 Sealer (2 coats @ 3 mils wet)

Topcoat: EMCAT+ EC2A-30 Satin (2 coats @ 3 mils wet), catalyzed with EC2B Catalyst at 10% volume

Dry Time: 18 hours for sealer, 24 hours for topcoat before testing

Application: HVLP spray equipment under ambient shop conditions

Application Notes: The sealer and topcoat were applied in accordance with ASTM protocols, including sanding, cleaning with a water/alcohol solution, and full curing under controlled humidity and temperature. Coating integrity and adhesion were inspected prior to chemical testing.

REAGENTS TESTED:

The test exposed the finish to different reagents categorized into Food Group and Solvent Group substances:

Food Group: Bourbon, black coffee, ketchup, mustard, olive oil, red wine, white vinegar, water (cold/hot/frozen), etc.

Solvent Group: Acetone, Clorox® wipes, Dawn® detergent, denatured alcohol, Purell®, isopropyl alcohol, lacquer thinner, mineral oil, etc.

Each reagent was applied in two forms:

Covered Spot Test (3.1.1): Covered with a cup for 15 min, 1 hour, and 4 hours

Uncovered Spot Test (3.1.2): Left open to air-dry for the same intervals

Post-test cleaning was done using a microfiber cloth with warm tap water.

TEST RESULTS:

Covered Spot Test Summary (ASTM D1308-20)

| REAGENT | 15 MIN. | 1 HOUR | 4 HOURS | POST-TEST RESULT |

| Bourbon Alcohol | No Effect | No Effect | No Effect | No witness line visible |

| Black Coffee (Hot) | No Effect | No Effect | No Effect | No witness line visible |

| Ketchup | No Effect | No Effect | Slight Stain | Stain Washed Away |

| Mustard (Yellow) | No Effect | No Effect | Slight Stain | Stain Washed Away |

| Olive Oil | No Effect | No Effect | No Effect | No witness line visible |

| Red Wine | No Effect | No Effect | No Effect | No witness line visible |

| White Vinegar | No Effect | Slight Swell | Slight Swell | Fully Recovered |

| Acetone | Slight Swell | Slight Swell | Slight Swell | Fully Recovered |

| Clorox® Wipe | No Effect | Slight Haze | Slight Haze | Fully Recovered |

| Dawn® Detergent | No Effect | No Effect | Slight Haze | Fully Recovered |

| Denatured Alcohol | Slight Blush | Slight Blush | Slight Blush | Fully Recovered |

| Isopropyl Alcohol (91%) | Slight Haze | Slight Haze | Slight Haze | Fully Recovered |

| Lacquer Thinner | Slight Soften | Slight Soften | Slight Soften | Fully Recovered |

| Mineral / Baby Oil | No Effect | No Effect | No Effect | No witness line visible |

Here is what jumped out to me in the covered spot test results:

There was “No Effect” from bourbon, black coffee, olive oil, red wine, and mineral / baby oil.

There were “Temporary Effects” with full recovery from white vinegar, acetone, Clorox® wipes, Dawn® detergent, denatured alcohol, isopropyl alcohol, and lacquer thinner.

There was “Minor Staining” with ketchup and mustard but it was easily cleaned away.

Now for the results of the…

Uncovered Spot Test Summary (ASTM D1308-20)

| REAGENT | 15 MIN. | 1 HOUR | 4 HOURS | POST-TEST RESULT |

| Bourbon Alcohol | No Effect | No Effect | No Effect | No witness line visible |

| Black Coffee (Hot) | No Effect | No Effect | No Effect | No witness line visible |

| Ketchup | No Effect | No Effect | Sight Stain | Stain washed away |

| Mustard (Yellow) | No Effect | No Effect | Sight Stain | Stain washed away |

| Red Wine | No Effect | No Effect | No Effect | No witness line visible |

| Acetone | No Effect | No Effect | No Effect | No witness line visible |

| Colorox® Wipe | No Effect | Slight Haze | Slight Haze | Fully Recovered |

| Denatured Alcohol | No Effect | Slight Blush | Slight Blush | Fully Recovered |

| Isopropyl Alcohol (91%) | Slight Haze | No Effect | No Effect | Fully Recovered |

| Lacquer Thinner | Slight Soften | Slight Soften | Slight Soften | Fully Recovered |

| Mineral / Baby Oil | No Effect | No Effect | No Effect | No witness line visible |

Here is a closeup look at some of the individual panels…

MY SUMMARY CONCLUSION:

The EMCAT+ system demonstrated exceptional chemical resistance under both covered and uncovered testing protocols.

Reactions — when present — were cosmetic, minor, and completely reversible. No permanent damage or witness lines were observed.

Result: EMCATt+ meets ASTM D1308-20 standards for clear coatings in demanding residential and commercial environments. Its clarity, adhesion, and resilience offer reliable protection without the use of isocyanates or aziridines.

That’s a good place to stop for Part 2.

In Part 3, we’ll wrap everything up; I’ll show you some examples of finished projects; and help you know if and when EMCAT+ is the right solution for you.

Part 3: A Better AND Safer Way to Finish with No Isocyanates or Aziridines

If there’s one thing I want you to take a way from this post, it’s this:

Traditional 2K coatings rely on toxic isocyanates or aziridines to complete the curing process. These compounds are known for serious health risks with repeated exposure.

EMCAT+ is different.

Our water-based system seals, beautifies and protects as well — and often BETTER — than solvent-based systems but WITHOUT toxic isocyanates or arizidines.

Instead, Emtech+ uses acid-functional resins and a proprietary blend of silane compounds to form a complete 2K bond — again, without those toxic compounds.

The result is:

• Exceptional adhesion and sealing, even on traditionally troublesome substrates

• The most chemical-resistant topcoat Target Coatings has ever made in its near 40-year history

• A full cure cycle in under 36 hours

• Extended pot life for real-world working conditions

• Significantly reduced health and safety risks for you and your working environment

Plus, EMCAT+ is engineered for versatility and reliability across a range of applications.

You can use it for…

Interior furniture and cabinetry

High-wear architectural millwork

Exotic hardwoods and oily substrates

Synthetic panels and decorative metals

Light-duty exterior applications

So, the question is…

Is EMCAT+ Right for You?

If you’re a professional finisher or serious DIYer using traditional 2K systems and want better safety, clarity, and substrate flexibility, yes, EMCAT+ is built for you.

Designed for use with HVLP, airless, air-assisted airless spray equipment, and automated applicators, EMCAT+ delivers premium results with a low hazard profile.

Ready to Experience EMCAT+?

I’d like to personally invite you to try the EMCAT+ ® Acrylic Polymer Coating System and see the difference for yourself.

After more than two years of research, development and testing (in the lab and in the shop), I consider it the new standard for professional-level wood finishing.

If you’d like to see the full ASTM report or a product spec sheet, please contact me here.

Do you have thoughts or questions about the performance of EMCAT+® and/or reducing your exposure to isocyanates and aziridines? Please share them in the comments section below.

Always been a fan of target coatings for the ease of application and repeatable results. Are there any plans to offer EmCat+ as a tinted top coat?

Camilo,

Thank you for your question. I am working on a pigmented version of Emcat+ EC2A, but it’s a few months away, and still in trials.

Please stay tuned and circle back in the 1stQ of 2026.

Cheers!

_JeffW-

Is this good for kitchen cabinets?

Larry,

Yes, it is perfect for kitchen cabinet applications, both new construction/build, and for refinishing/refin applications.

-JeffW-

Very exciting product. Thank you.

I’d greatly appreciate a post on your blog explaining the dangers of isocyanates and aziridine. I had a “big brand” rep drop off a jug of aziridine like it was water. I asked him about safety issues and he was completely oblivious. As an odorless product, I can only imagine how many of his clients are breathing in its vapors oblivious to the harmful effects. Likewise, I see “influencer” painters spraying 2k’s with a face mask respirator, unaware that this doesn’t protect against isocyanates. To me, this 2k craze seems akin to when MDF first came out, and no one knew about the danger of fine MDF particulates.

Would this finish work well for musical instruments. Currently looking at moving away from nitro lacquer.

Eric,

Yes, Emcat+ Si427 and EC2A are perfect for stringed instruments. We have a small but growing list of luthiers who have tried the Emcat+ products and have transitioned over to them for their builds.

-JEffW-

How does durability and ease of application compare with your em8000cv product?

David,

The durability of the Emcat+ EC2A-2K System is greater than the EM8000cv, even when the EM8000cv is crosslinked.

Please refer to the blog post that illustrates the ASTM chemical tests on the EC2A.

As for ease of application – EC2A-2K is applied in the same manner as the EM8000cv, but t does take different atomization pressures n gun setup’s to obtain a good final finish.

The EM8000cv and EC2A-2K are very different formulations, built with very different types of resins – there will be a minor learning curve to dial-in the EC2A.

-JeffW-

In the Guitars’s photo, how many coats of Emcat were applied? Just trying to get a feel for how it compares to other coatings?

Bob,

I will contact the luthier who made the guitar to learn how many coats he applied.

As a sidebar note, I have applied seven to 10 coats of the EC2A 2K top coat with excellent results and achieved a very high build.

-JeffW-

Bob, I have been applying 5-8 coats on full gloss guitar finishes, depending on how smooth coats flow out. If they flow out to only require sanding with 1500 grit & up to prepare for a full buffing 4-5 is adequate. Since the coats do not melt together witness lines will show if a cost is sanded through but they fully disappear in the buffing.

Jeff: I have been using EM6000 over em1000 sealer on all my guitar builds for the last four-five years. I use both exotic and domestic woods for both acoustic guitars and F-style mandolins. I have not had ANY issues with these coatings on any woods including cocobolo, padauk, east indian rosewood, ebony, and IPE. I do use these coatings with your cL 100 crosslinker. My question is, are these new materials (EMCAT+ and sealer) available in satin and what thinner is recommended? Can we use water to thin?

Mark,

Thank you for sharing your experiences with the Emtech EM1000 Universal Sanding Sealer and the Emtech EM6000 Production Lacquer with our readers. Yes, they are very function and easy to use coatings with or without the Emtech CL100 Crosslinker.

In regard to your question pertaining to if the Emcat+ EC2A-2K is available in a Satin sheen, yes it is. We offer the Emcat+ EC2A-2K in the following sheen options:

High Gloss – 95 Degree

Satin – 30 Degree

Flat – 10 Degree

Ultra-Flat – 5 Degree

All of these sheens are attained off-the-gun before any final polishing or rub-out is performed.

In regard to thinning the Emcat+ EC2A-2K Topcoat System, or the Emcat+ Si427 Sealer, the thinner of choice is distilled or well filtered fresh water.

As always, please feel free to contact our office to discuss the use of the Emcat+ System in greater detail.

-JeffW-

Hey Jeff,

So I’m curious i also build stringed instruments. Guitars and mountain dulcimers. My question is: I like to use epoxy for my pore fill and would like continue to do that. Will enact+ go over epoxy as well as em6000 which I have used in the past. Also do you have to use the sealer under the topcoat or can you apply the topcoat alone?

Thanks

Greg,

Thank you for your interest in using the Emcat+ 2K Topcoat System for your stringed instruments.

Yes, Emcat+ EC2A-2K can be used over cured epoxy. Ensure that you wash the cured epoxy surface with a solution of water and alcohol before you level sand it, and then lightly wipe the sanded epoxy one more time before applying the Emcat+ EC2A-2K.

Please feel free to contact our office if you have any further questions about using the Emcat+ 2K System.

-JeffW-

Like others who’ve commented, my primary interest in Emcat+ is for musical instruments. Since I build sporadically and only for myself or friends, I’m not sure I could use up a gallon before its shelf life expires. Any plans to offer this in quart sizes?

Jeff,

Yes! – We will be offering the Emcat+ System in quarts in 2026!

Stay tuned for more information about when they will be available.

Until then, the shelf-life of the Emcat+ Si427 and EC2A-2K Kits have been proven and expanded out to the 12-14 month range.

-JeffW-

I’d like to see a scratch test that compares EMCAT+ with 1k and 2K polyurethane, polyester, and nitrocellulose lacquer.

Jeff:

Please let us know ASAP when your new Emcat systems are available in quarts!