Given that people know that they should wear a mask when sanding, we still come across the wood finishing safety question of do I have to wear a mask when I spray a water based finish?

Yes, you do.

When manufacturers of water-based wood finishes began to come onto the scene with their products, the main marketing push was focused on the non-flammable and low volatile solvent content of these new products. Along with this focus was the premise that these products were user-friendly, and a lot less toxic to the surrounding environment. These messages were accurate in the big picture, but not a lot of focus was placed on the requirements to continue good industrial hygiene while using these new formulas. Skip forward 30+ years and we still have this wood finishing safety conversation. While the frequency of the question has decreased, it seems that not everyone is getting the message – yes, you must wear a protective respirator when you spray any water-based or waterborne coatings.

Why?

Let’s look at what we are working with in terms of the coating being used to build the answer. Water-based finishes are made from two or three types of resins – acrylic compounds, urethane resins of different formats, and in certain formulas oxidized natural oils. All these chemical compounds are film forming when blended with the correct type of water-soluble solvent. The keywords here are “film forming”. When a coating forms a film, it is designed to stick to a surface – usually a solid substrate.

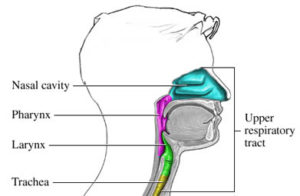

However, when the coating is atomized (or aerosolized) it becomes an airborne particulate. This particulate, when not controlled or contained, will land on any given surface – even if that surface is your upper respiratory tract, i.e sinuses, pharynx and larynx. This is where the big particles land and this is where you develop respiratory irritation and infections if not properly protected.

What type of mask should I use?

Consider this – if you made a big investment in spray equipment and put a lot of effort into making the space you are spraying in one of good quality, it only makes sense to go the extra yard and buy a good respirator. A full face or half mask respirator with NIOSHA approved P100 organic vapor cartridge with dust control pre-filters is recommended. P100 cartridges are designed to protect you from 99.9% of an airborne organic vapor, i.e. oil or water particulate. It is up to you on what type of mask (full or half) you want to wear. Full face masks offer complete facial protection – your eyes are included. However, half masks are certainly suitable and more comfortable. Also, ensure that the mask fits you properly. Good masks are not “one size fits all” in design. You need to ensure that vapor is not being inhaled due to a poor fit. Facial hair is also a matter when selecting your mask. When in doubt, get a fit test from your local industrial equipment supplier. Lastly, yes – you can get away with disposable N95 masks, or even a dust mask, but they are not going to afford you the protection you deserve.

What should I do if I am brush-applying a water based finish?

Brush-applied finishes certainly take the issue of airborne particulate out of the conversation, but it does not negate the use of wearing respiratory protection. It is important to consider off-gassing fumes when using a water-based finish. The cosolvents in these finishes are usually of two types of solvent compounds, ethylene (E-series) and the less toxic version – propylene (P-series) glycols, which is used in the entire Emtech suite of water-based finishes. Ammonia is also an off-gassing compound, and ammonia fumes can be irritating to the eyes, nose and throat if not properly ventilated out of the workspace. All of these solvents off-gas during the film formation and curing cycle, therefore we must take off-gassing solvents seriously. So whether you are brushing a clear coat or brush-applying a solvent based stain, you need to take off-gassing fumes into consideration.

What else should I be aware of?

Certain types of industrial waterborne coatings require a catalyst or crosslinker to develop a cured finish that will be durable enough for the assigned task. Waterborne catalysts, such as blocked isocyanate, are very toxic. Likewise, aziridine cross linkers are irritants and can cause violent allergic reactions when exposures to them are long term. These are very toxic chemicals, and you should really think about how to handle them and protect yourself before you venture into using these additives. Consult with the coating manufacturer to learn more about these additives if you really must use them and keep in mind that there a less toxic alternatives to be considered such as our CL100 Crosslinker, which is not aziridine-based.

Finally, with the constant chatter about wearing masks in public courtesy of COVID-19, we cannot take personal protection for granted. I believe that a lot of “lights” are turning on in our collective heads, and respiratory protection is now a lifestyle. Use the lessons learned in your woodshop and put them to use in your daily life. I think you will be glad you did.

I hope that this information has been helpful. Please feel free to share how you manage your industrial hygiene with us.

As always, stay creative and stay safe.

Jeff,

Do the P100 organic vapor cartridges degrade over time? How often should they be replaced?

Thanks,

Rob

Rob — Cartridges do have an expiration date, but I do not know how far out they can be used past the suggested date.

-JW-

Humidity and fumes will fill up the cartridges over time. The length of time depends on exposure. It is best practice to store the cartridges in a Ziploc-style bag when not in use.

Jon — Thank you for sharing. Yes, you are correct – cartridges, or the entire mask assembly, should be stored in sealed bag when not in use.

-JW-

Hi, how long after spraying a water-based poly should you wear a respirator in the same room? Are we talking hours or days?

Dave – Thank you for your inquiry. Once the overspray has dissipated you can remove you mask.

-JW-